Online Remote Calibration

CPCB Guidelines

CPCB vide No.C-12011/33/2017-18/Tech/520 dated 16th April 2018 has directed various SPCB’s to ensure that all industries falling under 17 categories & Grossly polluting Industries (GPI) should ensure that

- Calibration facility is available at the industry end

- Instruments are periodically calibrated & calibration data is also entered automatically into the system through the software installed at the industry and

- Remote calibration facility is available at each gaseous OCEMS

We Green Enviro at Front end and our IT Division NK Square at Back end has been working closely with various central & state agencies in the area of setting up continuous & real-time online pollution monitoring connectivity systems.

- We have developed and installed a cloud based software platform for the monitoring of real-time pollution parameters at Central Pollution Board, New Delhi. The platform is operational from August 2016.

- We have setup the necessary IT infrastructure and central server solution at CPCB, New Delhi and the current solution is receiving data from about 322 industries, 577 stations, 215 live camera streams and 920 parameters are being monitored on real-time basis.

- Our Data Acquisition Software solution is installed at over 100 locations all over India & monitors data pertaining to Ambient Air Quality, CEMS, Stack Emissions, Noise, Water Quality etc.

- OEM supplier of Telemetry Devices, A/D Converters, and Remote Calibration Hardware Solution for various industries across PAN India.

- We have successfully demonstrated Remote Calibration of gaseous OCEMS to CPCB on 5th, 18th & 27th April.

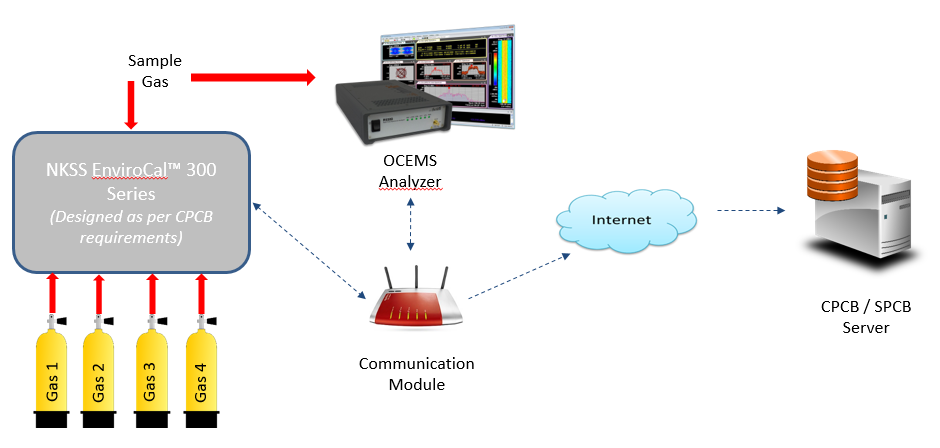

Remote Calibration Schema

Remote Calibration for CEMS

Remote calibration requests from CPCB server will be sent to the EnviroCal™ device/analyzer through client software at the station.

- Attach the corresponding gas cylinder along with Zero air cylinder to the EnviroCal™ device

- Software to operate the EnviroCal™ device, and to execute the calibration processing functions using the same device will be carried out.

- Remote Calibration i.e. SPAN Check and Zero Check to be performed on the analyzers, for which the current device is configured.

- Diagnostics data will be fetched from the analyzers at the time of calibration check is being performed on the analyzers.

Remote Calibration – Execution Process

- Initiate the remote calibration of Analyzer, as these instruments doesn’t need any external calibrator.

- Mode of the instrument will be changed from measurement to calibration.

- Server (CPCB/SPPCB) will send the request for Span/Zero calibration for the selected parameter.

- Span/Zero calibration requests will be sent along with the gas value that has to be calibrated.

- This request will be processed at the station DAS device

- If it is span then based on the gas value to be used to calibrate, the EnviroCal™ device will respond to the request and act accordingly to release the gas for the mentioned quantity.

- If the request is zero calibration, corresponding process will be done using the required gas cylinder for it.

- While doing this process the station PC/Modem will read the measurement data as well and uploads it to the server so that the data can be depicted in a graph for easy understanding of the process that is going.

- Once the calibration is completed, it responds with the results of it to the server.

- Calibration results will be displayed in the Server software along with the graph and status

Our Scope

EnviroCal (Calibrator) Module:

- Solenoid Valves – 5

- Flow Meter – 1

- Control System (Relay Setup & Power)

- Datalogger with Modem with LAN / GPRS

EnviroCal Module:

- Can be used for any make Gas Analyser

- 3 Channel Module

- Accepts Digital outputs RS232/RS485 from Analyser

- Will Perform Instrument Diagnosis like Alarms, Event, Healthiness, Flow, Temperature, Pressure, etc…

- Will Performa Zero & Span Check

- Can be used for Extractive or In-Situ

- Accepts even 4-20mA only for Calibration Check

CUSTOMER SCOPE

- CEMS Instrument in Running & Healthy Condition

- Manuals & Communication Protocols

- Analyser Software (if any)

- Calibration Gas Cylinders

- Regulators & Tubing

- Internet Facility

- Proper Earthing

- Skype / Whatsapp in your phone while CPCB performing Calibration (as they want to record the same)

Online Stack Emission (Insulation Photographs)